Profibus in Profinet sta industrijska komunikacijska protokola, ki ju Siemensovi nadzorni sistemi pogosto uporabljajo.

Čeprav sta imeni podobni, so tehnične karakteristike različne. Profibus in Profinet sta zelo različna protokola, ki uporabljata različne kable in konektorje.

Oglejmo si ta dva protokola in ugotovimo razlike.

Industrijska omrežja

PROFINET in OPC UA

V zadnjih letih se uporaba komunikacije preko OPC UA protokola hitro povečuje. Za to obstajajo tehtni razlogi:

OPC UA je neodvisen od platforme, ponuja najvišjo zmogljivost in preizkušene varnostne mehanizme, omogoča nemoteno komunikacijo s ostalimi aplikacijami in je prilagodljivo prilagodljiv za vsako zahtevo.

Splošno o IIoT (Industrial Internet of Things)

Avtomatizacija in računalništvo v oblaku se razvijata in združujeta v prostor, ki omogoča programiranje umetne inteligence (AI) za lažje izboljšanje produktivnosti in učinkovitosti s številnimi gospodarskimi koristmi. Skupaj z računalništvom v oblaku Internet in drugimi napredki z internetom smo zdaj sredi naslednje industrijske revolucije, ko rudarimo in podatke spreminjamo v informacije.

To evolucijsko obdobje se imenuje industrija 4.0 ali četrta industrijska revolucija, ki vključuje industrijski internet stvari (IIoT) in mehanizme digitalne transformacije, ki olajšajo to novo obdobje avtomatizacije v 4. generaciji. (more…)

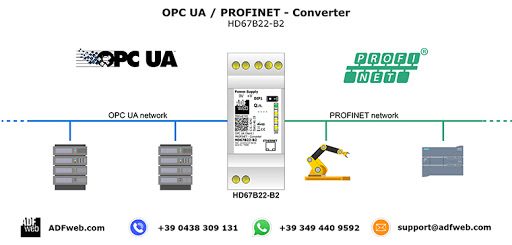

OPC UA / PROFINET converter

This series of products allows to integrate an OPC UA network with a PROFINET network.

In case of Siemens PLCs (or equivalent), it is possible to use S7comm protocol to get and set data into them from a OPC UA net. S7comm protocol is a Siemens protocol: this protocol is very good if it is necessary to get and set data from/to the PLC without changing the configuration of the PLC itself. This protocol will work as a debug protocol and the automation below the PLC will continue to work without any interferance.

- The HD67B22 is an OPC UA Client / PROFINET Converter and it allows you to read/write the data from one or more OPC UA Servers using a PROFINET Master (like a SIEMENS PLC etc).

- The HD67B45 is an OPC UA Server / PROFINET Master Converter and it allows you to read/write the data from one or more PROFINET slaves (like barcode scanners, printers, RFID, weight scales etc) using one or more OPC UA Clients.

- The HD67B46 is an OPC UA Server / PROFINET Converter and it allows you to interface a PROFINET Master (like a SIEMENS PLC etc) with one or more OPC UA Clients in order to exchange the informations between the networks.

- The HD67632 is a OPC UA Server / S7comm Converter and it allows you to connect a OPC UA Client with a Siemens PLC (or equivalent) in order to exchange the informations between the networks without changing the configuration and stopping the automation of the PLC.

The OPC UA communication can be encrypted, ensuring a SECURE and SAFETY communication.